Use Case for a Intelligent Supply Chain Management and Planning

Project Overview

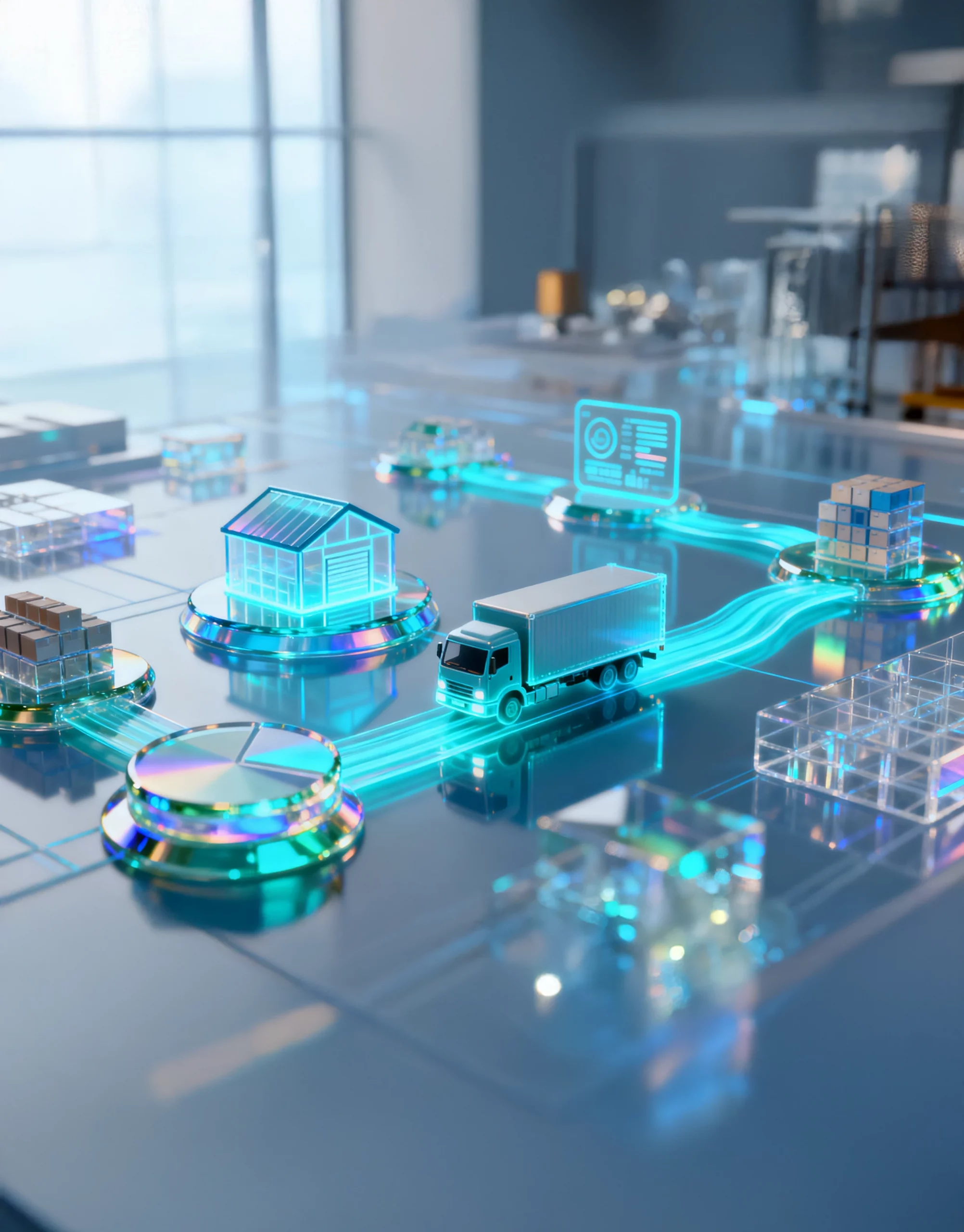

A global high-tech production firm located in southern Germany aims to revolutionize its supply chain management and planning processes. The firm utilizes SAP systems for daily, weekly, and monthly supply and demand reportings, traditionally managed through scorecards in Excel. The objective is to implement a sophisticated agent-based system to enhance data analysis, improve demand forecasting, optimize supply matching, and ultimately reduce costs and storage inventories.

Implementation Timeline and Phases

Phase 1

System Design and Data Integration (2 Months)

Activities:Developing AI agents specialized in pattern recognition, predictive analytics, and anomaly detection to analyze supply chain data.

Challenges Overcome:Ensuring compatibility and seamless data flow between the new AI system and legacy SAP systems without disrupting existing operations.

Phase 2

Development of AI Agents (3 Months)

Activities:Developing AI agents specialized in pattern recognition, predictive analytics, and anomaly detection to analyze supply chain data.

Challenges Overcome:Training AI agents to accurately interpret complex supply chain data and handle the variability in data formats across different reporting modules.

Phase 3

Testing and Validation(2 Months)

Activities:Conducting rigorous testing of the AI system with historical data, validating the accuracy of forecasts and recommendations.

Challenges Overcome:Adjusting algorithms to improve prediction accuracy and ensure the system's reliability in real-world supply chain scenarios.

Phase 4

Implementation and Staff Training (1 Month)

Activities:Implementing the system across the firm's supply chain operations, training staff on how to utilize the new tools and interpret AI-generated insights.

Challenges Overcome:Overcoming resistance to new technologies and ensuring staff are comfortable and proficient with the new system.

Phase 5

Ongoing Optimization and Scale-Up (Ongoing)

Activities:Continuous monitoring and optimization of the system, scaling up the solution to cover more complex aspects of the supply chain.

Challenges Overcome:Ensuring the system adapts to changing supply chain dynamics and scales effectively without performance loss.

S - Strategy:Crafting a strategic vision for integrating advanced AI technologies to transform supply chain operations, focusing on predictive accuracy and cost efficiency.

P - Prototyping:Developing and iteratively refining prototypes of AI agents to ensure they meet the firm’s specific requirements for data analysis and prediction.

A - AI Training and Understanding:Educating the AI system on the firm's unique supply chain dynamics using historical data and ongoing feedback loops.

R - Regulation and Compliance:Adhering to industry standards and data protection regulations, particularly in handling sensitive supply chain data.

K - Knowledge Transfer:Facilitating knowledge sharing sessions to ensure all stakeholders understand the benefits and functionalities of the new system.

Predictive Analytics and Machine Learning:Utilize advanced analytics to predict demand trends and supply chain disruptions.

Blockchain Technology:Implement blockchain for transparent and secure sharing of supply chain data across the network.

Internet of Things (IoT):Deploy IoT sensors to real-time track inventory levels and environmental conditions.

Robotic Process Automation (RPA):Automate routine data collection and entry tasks, reducing manual errors and freeing up resources.

Data Visualization Tools:Integrate sophisticated visualization tools to transform complex data sets into intuitive graphical representations for easier decision-making.

Improved Forecast Accuracy:Enhanced predictive capabilities leading to more accurate demand forecasting and supply planning

Cost Reduction:Significant cost savings from optimized inventory levels and reduced need for emergency procurement.

Enhanced Operational Efficiency:Streamlined operations through automated data processing and analysis.

Reduced Inventory Levels:Lower storage costs and reduced capital tied up in inventory due to better matching of supply and demand.

Expansion to Global Operations:Plans to extend the AI system to manage international supply chains, dealing with multiple regulations and market conditions.

Integration with Additional AI Technologies:Exploring the use of artificial intelligence in other areas of operation, such as logistics and customer service, to further enhance efficiency and responsiveness.

The introduction of an intelligent agent-based system for supply chain management at the high-tech firm dramatically transforms its operational capabilities, leading to substantial cost reductions, improved efficiency, and more robust forecasting mechanisms. This strategic initiative positions the firm to effectively meet future supply chain challenges and maintain its competitive edge in the global market.